Feature Rich LED Driver ICs: Enable High Power Automotive LED Headlamps

This impressive growth rate is driven by not only by LED’s high reliability, reduced power consumption and more compact form factors, but also by enabling innovative designs such as steerable headlights and antiglare dimming. Furthermore, in an automotive environment, all of these improvements must be optimized while also withstanding the rigors of the relatively caustic automotive electrical and physical environment. It goes without saying that these solutions must offer very low profile, compact footprints while simultaneously enhancing overall cost effectiveness.

Although LEDs have been used in daytime running lights, brake lights, turn signals and interior lighting for several years; it’s relatively recent that a handful of headlamp specific applications have emerged such as the Audi A8 and R8 and Lexus’s LS600h. However, in the past year, several automotive manufacturers have introduced LED headlamps in their most popular models. In 2014, Toyota offered LED headlamps in their bestselling car, the Toyota Corolla as seen in Figure 1. Additionally, several other models of Toyotas, Hondas, Nissans, Porsches and Audis offer LED headlamps in most of their upcoming models. Most estimate that the current LED headlamp market will surpass $3B in 2014.

Figure 1. 2014 Toyota Corolla LED Headlamp

One of the biggest challenges for automotive lighting systems designers is how to optimize all the benefits of the latest generation of HB LEDs. HB LEDs generally require an accurate and efficient DC current source and a means for dimming. The LED driver IC must be designed to address these requirements under a wide variety of conditions. As a result, power conversion solutions must be highly efficient, robust in features and reliability while being very compact and cost effective. Arguably, one of the most demanding applications for driving HB LEDs is found in automotive headlamp applications as they are subjected to the rigors of the automotive electrical environment, must deliver high power (typically between 50W to 75W) and must fit into thermally and space constrained enclosures, all while maintaining an attractive cost structure.

Automotive LED Headlamps

Benefits, such as small size, extremely long life, low power consumption and enhanced dimming capability are the catalyst for the wide spread adoption of HB LED headlights. Years ago, most manufacturers, such as Audi, Daimler and Lexus have used LEDs to design very distinctive driving lights or “eyebrows” around their headlights as part of their distinctive branding. There is a similar trend in LED headlamp designs with Acura’s Jewel Eye design, Porsche’s four quadrant design as well as numerous emerging designs.

The benefits of using LEDs in automotive headlights have several positive implications. First, they never need to be replaced, since their solid state longetivity of up to 100K+ hours (11.5 service years) surpasses the useful life of the vehicle. This allows automobile manufactures to permanently embed them into headlight designs without requiring accessibility for replacement. This enables their styling to be dramatically changed as LED lighting systems do not require the depth or area as do the HID or halogen alternatives. HB LEDs are also more efficient than halogen bulbs (and are soon to surpass HIDs) at delivering light output (in lumens) from the input electrical power. This has two positive effects. First, it drains less electrical power from the automotive bus, which is especially important in EVs and hybrids, and equally important, it reduces the amount of heat that needs to be dissipated in the housing eliminating any requirement for bulky and expensive heat sinking. Finally, by using arrays of HB LEDs and electronically steering or dimming them, they can be designed to optimize lighting for many different driving conditions.

Design Parameters

In order to ensure optimal performance and long operating life, LEDs require an effective drive circuit. These driver ICs must deliver an accurate DC current source and provide tightly controlled LED voltage regulation regardless of wide variations from the input source. An extreme voltage range from 4.7V during cold crank/stop-start scenarios, to 60V in load dump scenarios are found in automotive battery buses. But more commonly, the battery bus voltage will operate between 9V and 16V under normal conditions. As many of these new LED headlamp applications use 4 to 8 HB LEDs in series, with a collective voltage drop of 12V to 25V, and the battery bus voltage can range from 4.7V to 60V, a buck boost topology is necessary to power the LEDs as the input voltage can be above, below or equal to the required LED string voltage. Secondly, LED drivers must offer a means of dimming and provide a wide array of protection features just in case a LED open or short circuit is encountered. In addition to operating reliably from the electrically caustic automotive power bus, they must also be both cost and space effective.

A New Synchronous Buck-Boost HB LED Driver

Fortunately, there is a new solution to the dilemmas discussed, Linear Technology’s LT3791 LED driver. The LT3791 is a synchronous buck-boost DC/DC LED driver and voltage controller which can deliver over 100W of LED power. Its 4.7V to 60V input voltage range makes it ideal for a wide variety of applications, including automotive, truck and even avionics HB LED headlights. Similarly, its output voltage can be set from 0V to 60V enabling it to drive a wide range of LEDs in a single string.

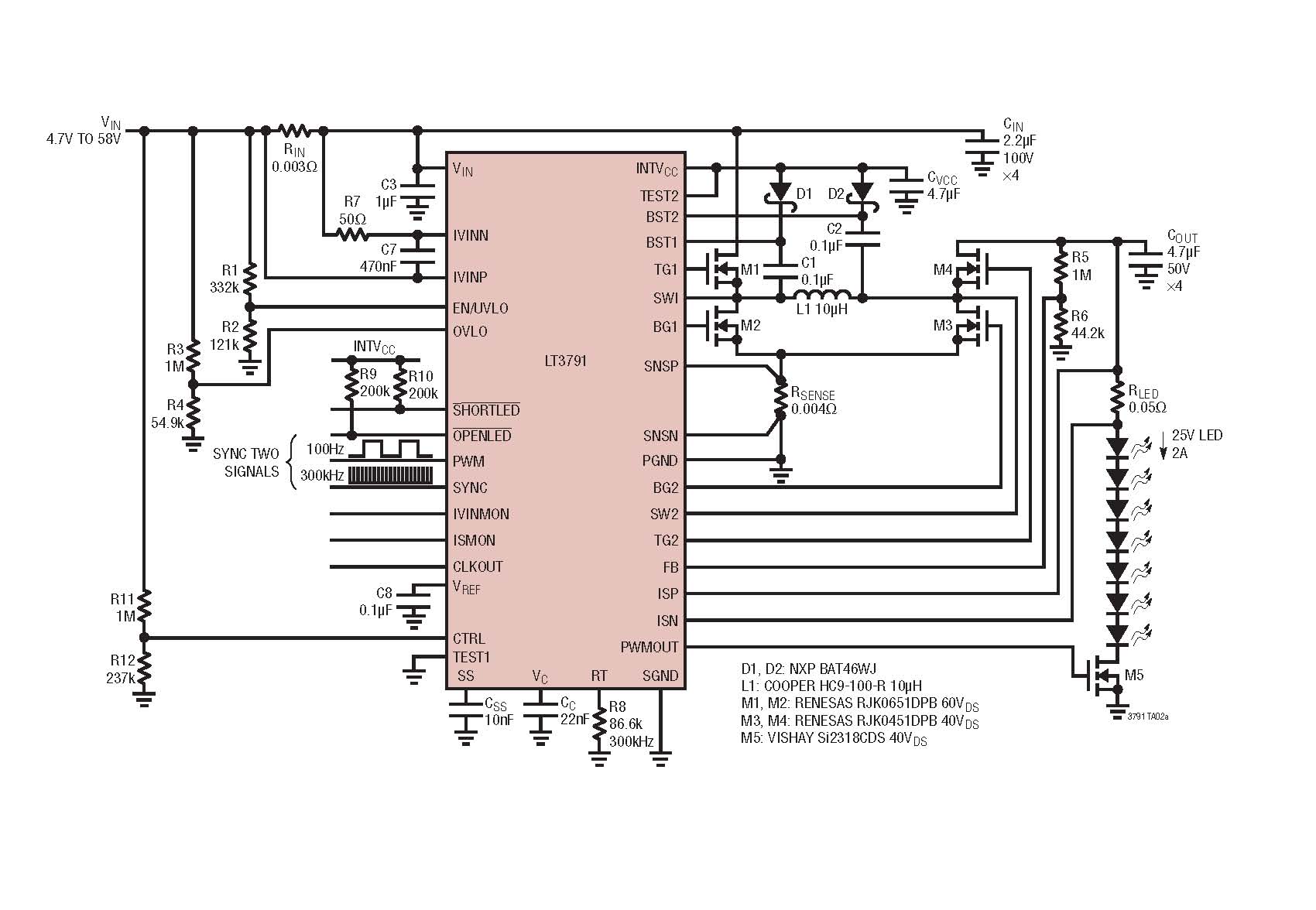

A typical 50W headlight application is shown in Figure 2. This application uses a single inductor to accurately regulate a 25V string of LEDs at 2A to deliver 50W of LED power. This circuit offers a 50:1 PWM dimming ratio which is ideal for anti-glare auto-dimming requirements. Both input and output (LED) current is monitored while fault protection is provided to survive and report an open or shorted LED condition.

Figure 2. 98% Efficient 50W (25V, 2A) Buck-Boost LED Driver with 50:1 Dimming Ratio. For better resolution click here.

Its internal 4 switch buck-boost controller operates from input voltages above, below or equal to the output voltage making it ideal for automotive applications. Transitions between buck, pass-through and boost operating modes are seamless, offering a well regulated output in spite of wide variations of supply voltage. The LT3791’s unique design utilizes three control loops that monitor input current, LED current and output voltage, to deliver optimal performance and reliability.

The LT3791 uses four external switching MOSFETs and can deliver from 5W to over 100W of continuous LED power with efficiencies up to 98%, see figure 3. In conventionally powered vehicles high efficiency is important as it minimizes the need for heat sinking enabling a very compact low profile footprint. However, in EVs this power savings adds valuable miles of vehicle range between charges.

LED current accuracy of +6% ensures constant brightness of each LED in a string while + 2% output voltage accuracy offers several LED protection features and also enables the converter to operate as a constant voltage source. The LT3791 can utilize either analog or PWM dimming as required by the application. Furthermore, its switching frequency can be programmed between 200kHz and 700kHz or synchronized to an external clock. Additional features include output disconnect, input and output current monitors, and integrated fault protection.

Figure 3. LED Efficiency in Figure 2

Conclusion

The swift adoption of LED headlamps into a wide array of new car models is being driven by an insatiable demand for higher performance and cost effectiveness which LEDS offer. However, these demands are enabled by new HB LED driver ICs. These new LED drivers must provide constant current in order to maintain uniform brightness, regardless of input voltage or LED forward voltage variations, operate with high efficiency, provide very wide dimming ratios and have a variety of protection features to enhance system reliability. Of course, these LED driver circuits must also offer a very compact, low-profile and thermally efficient solution footprint. Linear Technology is continually redefining its family of LED drivers to meet these challenges with HB LED driver ICs such as the LT3791. In addition, we have developed an entire family of high current LED driver ICs aimed specifically at automotive applications, ranging from forward lighting headlamps to LCD backlighting. As automotive lighting systems continue to demand higher performance LED drivers, designers will have innovative IC solutions for them.

About the author:

Jeff Gruetter is Sr. Product Marketing Engineer, Power Products at Linear Technology.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News