A Systems Engineering Approach to Managing Complexity

Winning new customers and establishing market leadership requires getting the best product at the highest quality faster than the competition. To achieve this, high performing engineering leaders take a Systems Engineering approach, particularly when the product or the development process itself has a high degree of complexity. Those who don’t, run the risk of being left behind.

Systems Engineering enables engineering organizations to approach the design of complex systems and its impact across multiple engineering disciplines: mechanical, electrical, and software. With this approach, customer requirements are defined early in the development cycle and are implemented through design and system validation—from concept to operation. Systems Engineering isn’t just an approach to product development, it’s a consideration throughout the entire product lifecycle, including product support and maintenance.

By making Systems Engineering a core discipline, businesses improve collaboration across disparate teams, shorten development cycles, and improve overall product quality.

The Current Situation

Many discrete manufacturing companies in high-growth industries haven’t had the time to proactively adopt a Systems Engineering approach to product development. Company acquisitions, accelerating customer demand and competitive pressures have resulted in the adoption of disjointed product development processes and tools.

Without well-defined end-to-end processes and tools to support them, these businesses are not able to take advantage of high value collaboration between engineering disciplines (mechanical, electrical, and software). Related design artifacts can’t be used across product lines, thereby limiting design reuse and introducing inconsistencies and potential quality problems. A lack of standardization across the systems architecture and processes leads to errors and redundancies, increasing engineering, manufacturing and service costs. In addition, lower quality products are more difficult and costly to maintain.

Disjointed processes make it virtually impossible to test and analyze the product in the context in which it will be used, leading to costly late stage rework. With no linkage or flow between system artifacts (e.g. requirements, designs, models, test, verification etc.), there is also a lack of traceability, increasing the time it takes to analyze data and generate reports to address compliance requirements. As a result, completed product designs don’t get to manufacturing on time, affecting overall time-to-market. These delays lead to lost market opportunities — potential sales that may go to competitors.

The Solution- Key Elements of a Systems Engineering Approach

A Systems Engineering approach addresses product development challenges by applying systems engineering throughout the product lifecycle. By applying a systems engineering “lens” in each stage of product development, product requirements can be verified and validated, a flexible and modular product architecture can be created, and high product quality is ensured. As a result, better products get to market sooner.

There are three key elements that form the foundation of a systems approach to building complex products. While there are a wide range of tools, methods, and practices in the systems engineering toolbox, these elements are needed to form a solid foundation.

1) Connect requirements, design, and test for multi-disciplinary collaboration

Well-connected assets and processes enable systems engineers to manage requirements in architecture, design, implementation, and test—with real-time, iterative collaboration across all engineering disciplines. Conventional "siloed" engineering environments are linked—so that systems, mechanical, and electrical engineers spend less time communicating across organizational and geographical boundaries. With an integrated collaborative approach, interdependencies can be recognized and changes can be evaluated instantly, improving efficiency and productivity.

2) Enable validation of lifecycle assets from requirements to test as they are created and changed

Proper requirements validation requires extensive closed-loop analysis, modeling, and simulation. Validation begins at requirements definition and continues throughout the lifecycle so that changes are always accepted, managed and documented in a controlled manner. As each change is accepted, the requirements must be revalidated by examining the artifacts used to do the initial validation. Focusing on customer needs early in development and throughout the product lifecycle reduces late stage rework and ensures the final product meets target objectives for functionality, cost, performance and quality.

3) Verify as-designed and as-built product against design and requirements throughout the product lifecycle

Verification and test activities should be planned soon after requirements are defined and modified iteratively as requirements change. As-designed and as-built product must also be verified against requirements, beginning early in the lifecycle and continuing through final system verification and test. By employing a wide variety of analysis, modeling, simulation, verification, and testing across the lifecycle, engineers can easily ensure product quality and compliance, while related artifacts, such as models and simulation results, are automatically maintained and tracked.

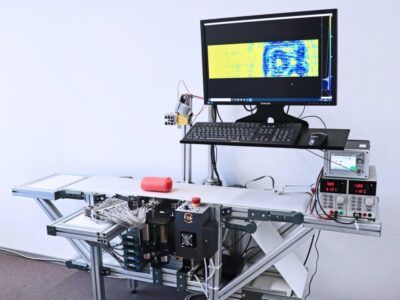

Research Study highlights Systems Engineering Value

Evidence to support the benefits of a Systems Engineering approach can be found in a paper published by The International Council on Systems Engineering (INCOSE) and written by Eric C. Honour, entitled “Understanding the Value of Systems Engineering” The paper examines several statistical studies that seek to quantify the value that Systems Engineering brings to manufacturers.

In 1995, Boeing performed a study to evaluate the effectiveness of using system engineering methodologies. Three similar systems used in the manufacture of airplanes were built at the same time using different levels of system engineering (SE). In this study, a number of SE practices were varied, primarily relating to defining and managing requirements, subcontract technical control, design reviews, integration methods, and acceptance testing.

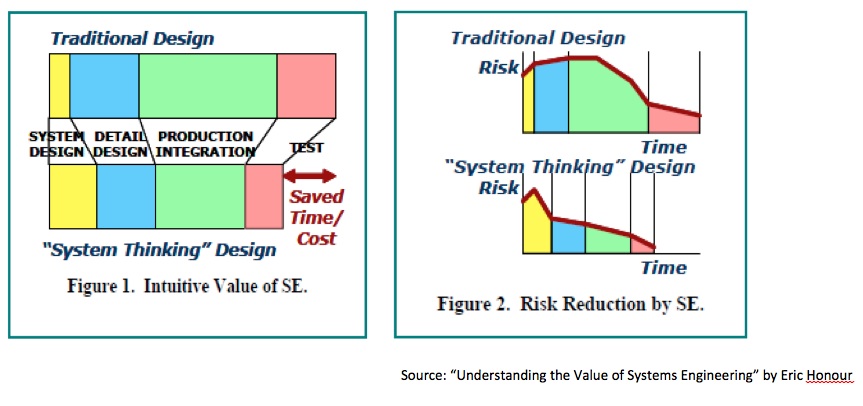

Mr. Honour ‘s premise is that an intuitive understanding of the value of system engineering comes from utilizing a “system thinking” approach (See Figures 1 and 2 below). The premise concludes that placing more emphasis on the system design creates more rapid integration and testing. This results in saving both time and money while also improving product quality. In addition, spending more time on the system design reduces project risk early in the process while shortening the schedule and reducing cost.

The project examined data from a number of industry studies (including Boeing, NASA, MIT Sloan Management, and INCOSE) in order to support the intuitive beliefs. The following conclusions were made based on data analyzed from these studies primarily focused on time, effectiveness, quality and cost.

Systems Engineering in Practice

Continental AG

Continental AG, a leading global automotive supplier, has implemented a Systems Engineering approach to handle engineering within their own company as well as with OEMs and suppliers. With automobile manufacturing growing in complexity due to the large volume of software-driven features, a typical development project at Continental can generate, realize and validate as many as 11,000 to 12,000 requirements. By adopting a System Engineering approach, Continental has seen a huge time savings in managing the exchange of requirements with partners and has significantly improved accuracy on initial imports of documents, eliminating costly rework. They have also reduced change cycle time for predictable on-time delivery of new products and features, enabling them to offer innovative products ahead of the competition. With a Systems Engineering approach, Continental has been able to meet target objectives for cost, performance and quality.

TRW

TRW, another of the world’s leading automotive suppliers, employs a Systems Engineering approach in the manufacture of its “slip control systems” – electronically controlled elements of today’s automotive systems that provide safety and convenience features such as anti-lock brakes and traction control. TRW’s slip control systems combine mechanical, electrical, and software components in a complex system that must function properly to meet the safety standards of ISO 26262. TRW has replaced siloed, and in many cases, manual product development processes with an integrated multi-disciplinary collaborative process that links product development functions for cross-discipline engineering analysis, design and verification. This in context system analysis has enabled TRW to improve and optimize the final system design as well as guarantee safety, high quality and reliability. The Systems Engineering approach has also enabled TRW to reduce risk and liability and streamline compliance reporting — while at the same time lowering costs for engineering, manufacturing and service.

Conclusion

Global markets are the new normal for many manufacturers. Highly segmented and dynamic customer preferences, rapid technological innovation and distributed engineering teams greatly affect your ability to outdistance the competition. To overcome these challenges and deliver high quality products to market on-time and on-budget requires a comprehensive, multidisciplinary approach that coordinates all engineering disciplines. Through Systems Engineering, product development organizations can tackle and manage complexity and innovate rapidly and efficiently. Businesses become market leaders—increasing revenue, market share, and competitive advantage.

PTC

PTC’s technology solutions help customers transform the way they create and service products across the entire product lifecycle – from conception and design to sourcing and service, enabling them to achieve sustained product and service advantage. For more information, go to www.PTC.com.

About the author

Derek Piette is a Product Management Director at PTC and is currently responsible for the product direction of PTC’s System Requirements and Validation solution within the ALM Segment. Mr. Piette also manages the integration between Windchill and Integrity. He has spoken at numerous events on the topics of hardware-software interaction, electronics and high tech, and PTC’s product direction.

Since joining PTC in 2003, Mr. Piette has held several positions within Product Management involving CAD data management, CAD integrations, requirements management, and complete product structures. Prior to joining PTC, Mr. Piette worked as an electrical and systems engineer for a semiconductor capital equipment supplier, KLA-Tencor.

Mr. Piette attended WPI where he earned his bachelor’s degree in electrical engineering.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News