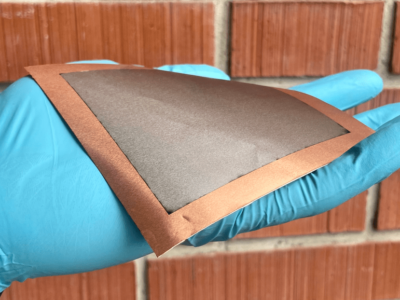

3D printed smart heat pipes with embedded sensors and energy harvesting

CSEM in Switzerland is developing 3D printed heat pipes with embedded sensors and energy harvesting for the European space industry. As well as satellites, the smart pipes could have uses in areas ranging from industrial heating and cooling systems to irrigation mechanisms for Industry 4.0.

The €2 million Advanced Heat Exchange Devices (AHEAD) project aims to develop thermal control systems with 3D-printed pipes with temperature sensors and heating elements embedded in the pipe’s inner surface. The system will also include an energy recovery device to power the embedded electronics and enable automatic, wireless data transfer.

“Broadly speaking, we aim to develop technology bricks that can be used to integrate electronic components like cables, connectors and sensors into many different kinds of 3D-printed objects,” said Hervé Saudan, a project coordinator at CSEM.

“The ability to embed sensors into process equipment will be an important feature of Industry 4.0. The data collected by these sensors can be used to feed artificial intelligence algorithms for process control, process optimization and predictive maintenance.” The consortium hopes to bring its technology to the pre-industrial stage and make it suitable for a broad range of applications including industrial heating and cooling systems, irrigation mechanisms, surgical instruments and implants, machine tooling, robotics and automotive parts.

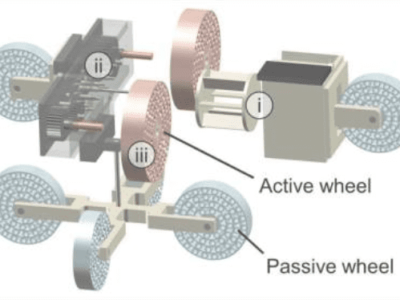

The two applications that the project engineers are currently targeting are space modules and the CERN’s new particle detectors.

Thales Alenia Space (TAS) is studying how the sensor-equipped pipes could be employed in the International Space Station’s pressurized modules and in NASA’s future Lunar Gateway space station. TAS also plans to install the pipes in two-phase mechanically pumped fluid loops, which are a type of thermal control system used in its telecommunications satellites.

“The lighter, more compact design enabled by the pipes, along with improved precision in temperature measurements and faster assembly, are key benefits for us. They allow for better thermal control, which is a critical factor in all space systems. That gives us a significant competitive advantage over rivals in Europe and the US,” said Martin Raynaud, a thermal specialist at TAS.

CERN plans to use the sensor-equipped pipes in the thermal control systems for the silicon detectors its engineers are currently developing. The detectors will be used to identify particles released from a multitude of collisions.

The thermal control systems of the detectors will be able to run without the complicated cable set-up usually required, saving space and allowing for better thermal control through temperature readings taken directly at strategic points. The new technology will also let engineers replace existing coolants with ones that are more effective and less damaging to the environment.

“Technological breakthroughs are often needed before particle detectors can deliver the extraordinary performance that’s expected of them,” says Paolo Petagna, a CERN project manager. “These breakthroughs could lead to a totally new concept with applications well beyond the one originally intended, bringing benefits to important industries. That’s what we’re seeing with AHEAD.”

AHEAD is a EU Horizon 2020 project being carried out under Phase 2 of ATTRACT, a broad R&D program spearheaded by CERN. CSEM is also part of the advanced 3D printing manufacturing centre opened this week in Neuchatel.

Related articles

- 3D printing a complex heat sink in copper

- Heat pipes integrated in PCB layers boost thermal performance

- Solid state heat pump project for refrigerant-free cooling

- First 3D printed motor leads to startup

Other articles on eeNews Power

- Cooling boost for Irish university data centre

- Odyssey readies 1200V vertical GaN to take on SiC

- onsemi $450m boost to European silicon carbide wafer plant

- ABB takes stake in Samotics to expand AI predictive maintenance

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News