High-voltage resistant temperature sensors for connectors in electromobility

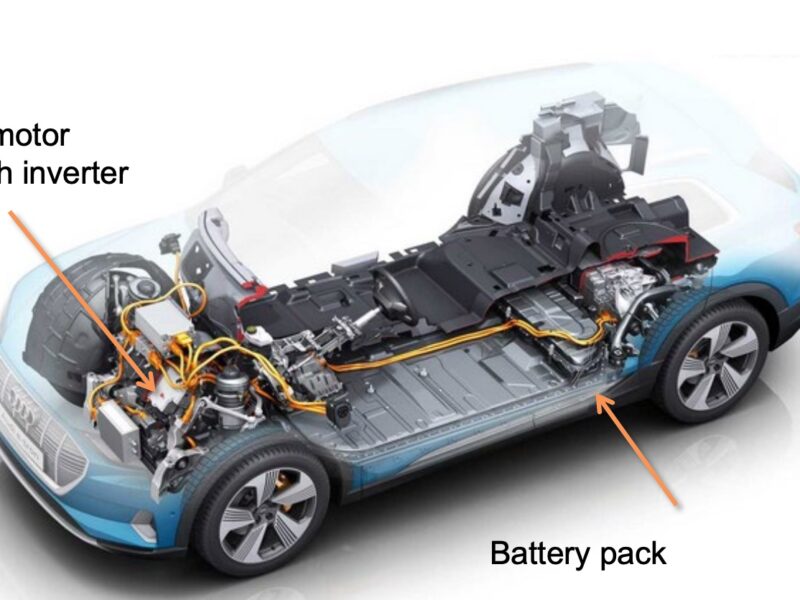

High-voltage batteries for electric vehicles (xEV) have nominal voltages of up to 1000 V, which requires corresponding high-voltage resistance of all system components. In order to achieve high drive powers of sometimes significantly more than 100 kW via inverter and motor, currents occur that are in the triple-digit range. These high currents, in conjunction with line and contact resistances, lead to not inconsiderable power losses and thus to heat loss, since the currents are included in the calculation quadratically: PV = I2 x R. Thus it becomes clear that even small resistances in the milliohm range lead to relatively large losses and thus to heating that can assume critical values.

For this reason, critical contact points in xEV – for example connectors between battery and motor inverter – must be thermally monitored. If overheating is imminent, the current can then be throttled in time. NTC-based temperature sensors that initiate a derating of the current are suitable for monitoring the temperature at critical points. Figure 1 shows the control principle.

Electromobility places completely new demands on the development and design of NTC temperature sensors – especially for integration in high-voltage systems. These include:

- High voltage resistance

- Short response time

- High temperature resistance

- High accuracy

- Possibility of integration directly into connectors

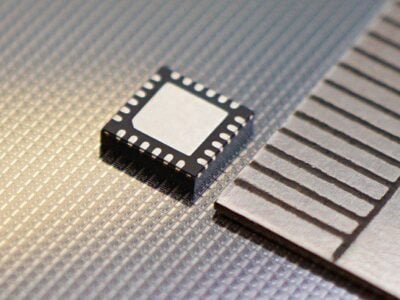

The challenge was to find a material that had high electrical insulation properties, but also very good thermal conductivity, in order to develop a design in which an NTC element could be integrated. In addition, a high temperature resistance had to be offered. A sleeve made of a special ceramic in which the sensor element is integrated proved to be suitable. Figure 2 shows the temperature sensor developed in this way.

The design of the new temperature sensor for integration into connectors. By using a ceramic sleeve in which the NTC element is integrated, the required high voltage resistance and short response time could be realised.

Several tests have proven that the newly developed TDK temperature sensor meets the requirements placed on it. The high-voltage test showed a dielectric strength of 5 kV DC of the sensor head, which clearly exceeds the system voltage of 1 kV DC. The required short response time was also achieved. This is particularly important in order to initiate derating in good time in the event of sudden overheating. Here a τ value (63%) of clearly <10 s seconds was determined in a typical installation situation. The permissible temperature range is -40 °C to +150 °C, with short-term exposures of 180 °C permissible.

The accuracy of the sensor is also an important aspect. Only if this is sufficiently high can a timely and at the same time not too early derating be initiated. With the new sensor, there is a maximum deviation of ±0.2 K at 25 °C and the resistance value R25 is 10 kΩ with a tolerance of 1 percent.

The upper plastic part of the sensor is designed in such a way that – depending on the customer’s requirements – it allows a variety of mounting options such as shrink-on, clip-in or clip-on.

All in all, the new sensor with its good electrical, thermal and mechanical values contributes to making electromobility safer and more efficient.

www.tdk-electronics.tdk.com/de/inquiry

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News