Mentor ecosystem to speed cockpit electronics development

In an environment characterised by the digitalisation of vehicle functions, it is becoming increasingly difficult for car manufacturers to keep control of technical developments – evolution is progressing too fast, the landscape of suppliers, engineering service providers and new, highly specialised company start-ups is too differentiated. In addition, the complexity of the nested automotive supply chains makes the rapid development and provision of innovative digital functions more difficult. “Some OEMs are therefore turning away from traditional supply chains in order to regain control of developments,” explains Michael Ziganek, Managing Director of the Automotive Business Unit of the Siemens company Mentor.

Against this background, Mentor is addressing the specialist public with a comprehensive range of software, hardware and services. Under the name VCOS2 (Vehicle Cockpit Consolidation Solutions), it supports developers in designing and developing cockpit systems that can be accommodated on a single computationally powerful ECU based on ARM architecture. The offering, Mentor promises, will enable automotive designers to slash costs, speed time to market and improve the user experience without compromising the automotive industry’s stringent cybersecurity and functional safety requirements.

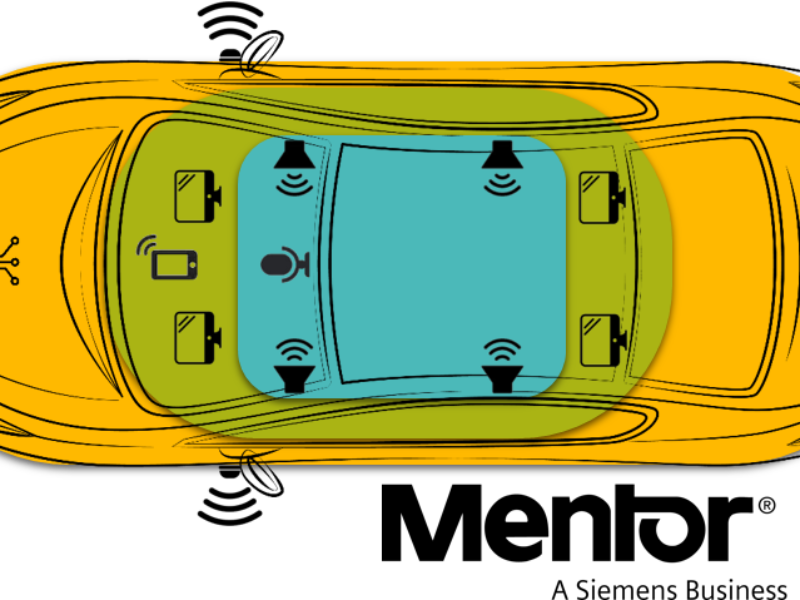

Combining instrument clustering and in-vehicle infotainment (IVI) in one computing platform saves space and costs, Mentor argues. Added to this are technical advantages: The fusion of instrument cluster and IVI functions, which can run with different operating systems on one ECU, eliminates latencies that exist in data exchange between distributed ECUs and supports multiple levels of security domains (ASIL and QM). The Mentor solution also offers graphics, video and audio sharing and other features. “In order to isolate domains and increase functional safety, developers of automotive electronics instrument cluster and IVI systems today usually distribute the corresponding functions over several ECUs,” explains Ziganek. The sophisticated separation of the tasks that run on one ECU in VCO2 makes this costly and time-consuming approach obsolete.

In traditional, multi-structured supply chains, teams also often focus on demarcating sets of functions with minimal interaction. Here again, the Mentor approach offers an advantage, as it takes advantage of the rich functionality and high computing capacity of today’s highly integrated single-chip systems to implement different domains at the security integrity level on the same device. As a result, the integration of instrument cluster and IVI systems in one ECU is not only possible, but also an architectural advantage as engineering teams need to consolidate more systems in fewer in-vehicle ECUs.

Mentor’s VCO2S solution is available in three different options, allowing customers to get started quickly with consolidated cockpit systems:

- VCO2S Base with basic features such as software IP and services for a consolidated cockpit design VCO2S Base can be ported to the customer’s target hardware as a reference design.

- VCO2S Flex is a scalable solution – which can be extended to a fully customised cockpit consolidation system – with IP, system, software and hardware services each optimised for operation on the customer’s target hardware.

- VCO2S Unique extends VCO2S Flex to include technical management and integration of SoC vendors and tier-one hardware suppliers, with Mentor acting as a tier-one software supplier. The VCO2S Unique option is aimed at automotive manufacturers.

All three versions include functional safety libraries (ASIL-B), security features and architectures for shared graphics, video and audio content between ASIL and QM domains. All versions feature CAN and Ethernet connectivity to the vehicle and support for Bluetooth, WLAN, FM/DAB radio, 4x cameras and automotive audio. Communication between QM and the ASIL-B domain is implemented by the Mentor Communication Framework (MCF) with safety certification processes. The VCO2S Flex and VCO2S Unique solutions can be enhanced with additional functionality upon customer request.

The product rollout alone is not enough for Mentor. The entire vehicle electronics ecosystem is currently undergoing rapid change. Designers are working on combining the single-function ECUs, which have been distributed throughout the vehicle up to now, into zonal and central ECUs and on transferring the function of the classic ECUs to the software level (“virtual ECUs”). For this reason, the Mentor Group is currently working on the future platform VCO3, which will enable a consolidated ECU model.

With these developments Mentor is also pursuing a strategic goal as a company: “We want to establish ourselves within the automotive industry as a central service provider for the development of such platforms,” says Ziganek.

More information: https://www.mentor.com.

Related articles:

Siemens opens its arms to automotive electronics developers

Siemens AUTOSAR tool adds time critical Ethernet protocol stack

The Criticality of the Automotive E/E Architecture

Cable harness: The unseen challenge

Mentor further expands automotive expertise with takeover

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News