Consortium submits ideas to make vehicle electronics simpler, more robust

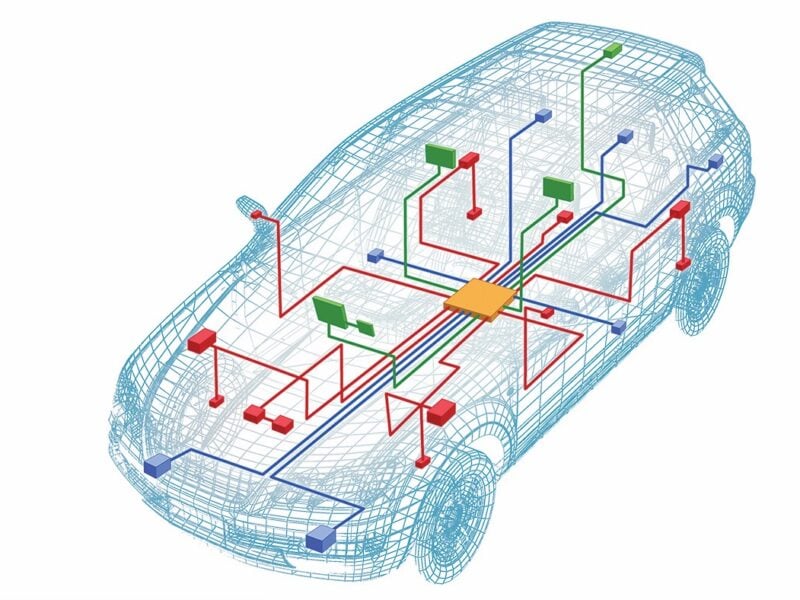

This increased functionality of vehicles, which is the aim of 3Car – and, by the way, practically the entire automotive industry -, requires a new system approach in vehicle architecture to support electromobility and highly automated driving. In 2014, when 3Car launched its activities, cars already contained between 70 and 100 networked ECUs. Driven by growing demands for comfort, functionality, efficiency, safety and environmental compatibility from OEMs and their customers, this number has increased further in the meantime. The European project “Integrated Components for Complexity Control” (3Ccar), has stood up to this challenge. 48 partners from 14 countries have developed novel highly integrated semiconductor-based solutions.

The primary goal of the project was to reduce complexity and simultaneously increase the reliability of electric and autonomous vehicles. To this end, 3Ccar has developed a new system approach in vehicle architecture: The vehicle architecture will be reorganized in so-called vehicle domains. They enable functional and task-oriented coordination. This reduces complexity despite increasing requirements, greatly easing the development of electric, autonomous vehicles.

The vehicle architecture

The individual control units are integrated into the corresponding domains. Functionalities such as steering, braking and drive are coordinated from there. A few powerful domain controllers are introduced for this purpose. These are based on multicore automotive processors and heterogeneous SoCs. For example, the conventional powertrain becomes a domain. Fewer, but more highly integrated ECUs not only make complexity controllable, but also increase robustness.

The smart battery

Up to now, high cabling costs in vehicle batteries have led to high costs and lower reliability. In cooperation with the Fraunhofer Institutes IISB and IPA, 3Ccar has developed a modular and flexible concept for future batteries for electric and hybrid vehicles. The sensors and electronic components are integrated with the battery cell network instead of at battery pack level. This approach is completely new, simplifies battery management and offers the opportunity to produce competitive “Smart Batteries Made in Europe” in the future. The system contains fewer individual parts, is therefore less prone to faults and thus contributes to the robustness of the vehicle architecture.

Safety shutdown for fuel cells

With the help of Infineon, Daimler, Fraunhofer IISB and Lange Aviation, 3Ccar has developed a new safety cut-out for discharging fuel cells. Compared to today’s competitor products, this is more compact and can be reused. While previous concepts can only be used once because they are destroyed by activation, the new development can short-circuit the fuel cell several times and then release it again.

The drive motor

Together with Siemens, 3Ccar has realized an electric drive with a higher power density than comparable products. Thanks to its compact structure, it enables high vehicle performance in demanding installation spaces. In addition, the new drive motor is more efficient and offers greater reliability.

Routing for electric vehicles

OTH Amberg-Weiden university developed a special vehicle-to-network (V2N) communication system for electric vehicles. The aim was to provide a basic service capable of handling the entire route planning process, using a server-based route planning system in road networks combined with information on charging stations. Using this server-controlled routing system, it was possible to determine specially tailored and optimised routes for electric vehicles.

Responsible for project management and coordination within the research group was chipmaker Infineon Technologies. The project was funded by the European Union, the German Federal Ministry of Education and Research (BMBF) and other participating states as well as partners from industry. The total project volume amounted to €54 million. 3Ccar started in 2015 and lasted 41 months. The eleven German partners now present the research results in their own final report.

Among others, chipmakers NXP, Murata, On Semiconductor and STMicroelectronics were involved in the project. Daimler and BMW participated from the vehicle manufacturers’ stock. Technology companies such as TTTech, Qinetiq, Siemens, the automotive suppliers Valeo and AVL as well as the research institutes Fraunhofer, VTT, Virtual Vehicle and OTH Amber-Weiden university were also involved.

Further information is available at: https://3ccar.eu/

Related articles:

The Criticality of the Automotive E/E Architecture

Number of automotive ECUs continues to rise

Infineon, TTTech Auto show computing platform for autonomous driving up to Level5

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News